Testing

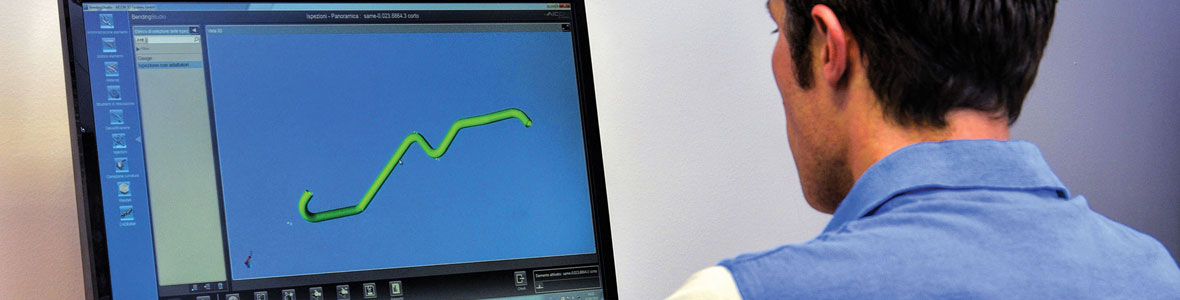

Thanks to the presence of internal laboratories equipped with numerous instruments, SAG TUBI is able to perform testing and controls for the monitoring and certification of its products and production processes.

Dimensional controls: optical tube measuring system, laser scanning, profile projectors, roundness and roughness testers, surface layers measuring instrument;

Performance tests: impulse pressure testing from 80bar to 1000bar with temperatures up to 150°C, 10bar pressure testing in water, static pressure tests up to 2000bar, pressure-drop testing, sensitive detection tests for gas leakages to a minimum 0.01g/year, contamination tests, salt spray endurance tests, dynamometric tensile testing, material hardness testing, internal tube inspection with endoscopic camera, free-flow fluid testing.